About Air /Industrial Blowers?

-

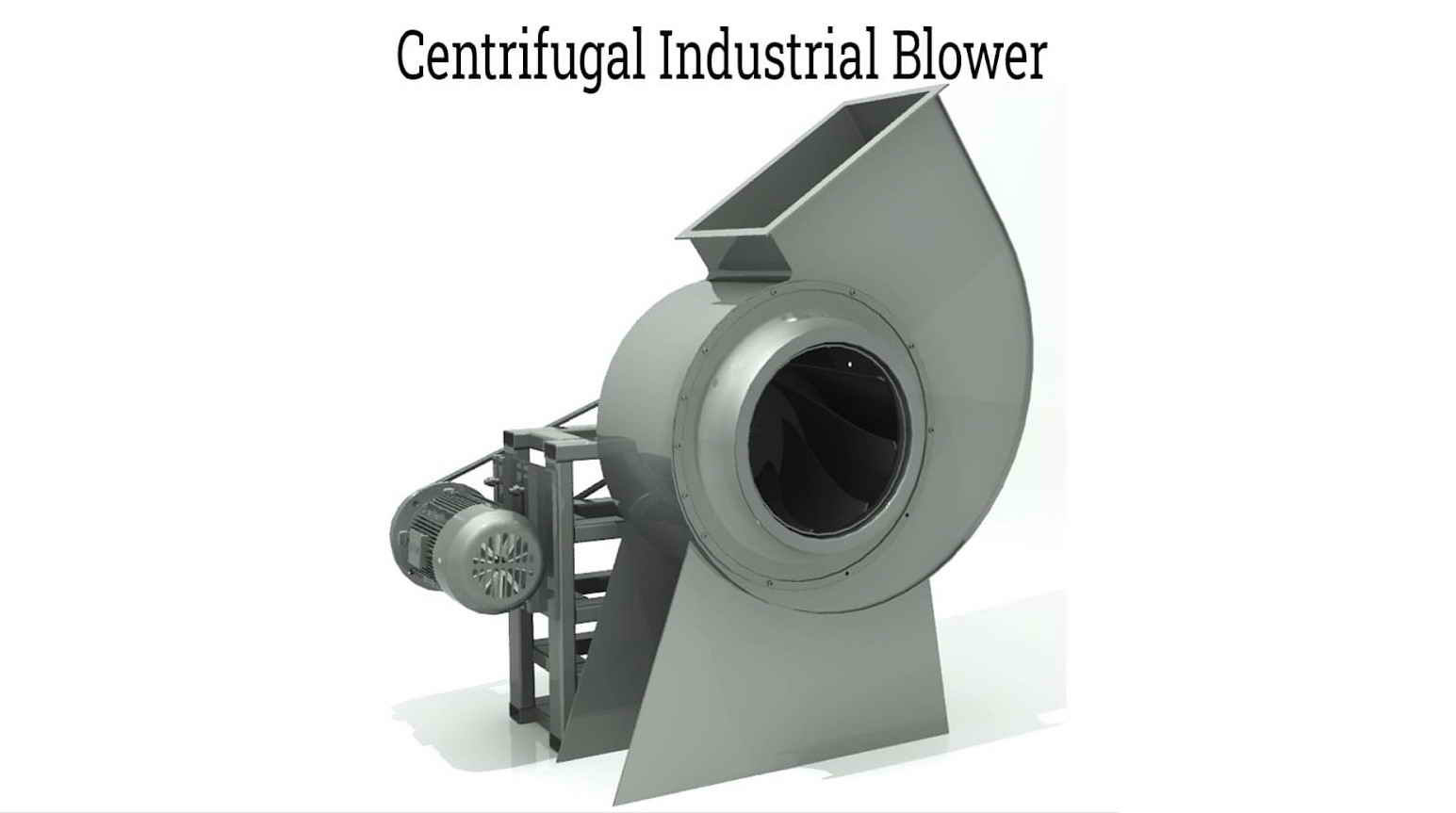

An industrial blower is a device that enhances the air flow effectively and efficiently using an electric motor, impeller, and airfoils enclosed in a tightly sealed housing. The purpose and function of industrial blowers is to increase airflow and remove contaminants, dust, dirt, and particulate matter. They are highly technical devices designed to produce higher pressure than a fan at a ratio of 1.11 to 1.2, which places them somewhere between a fan and a compressor.

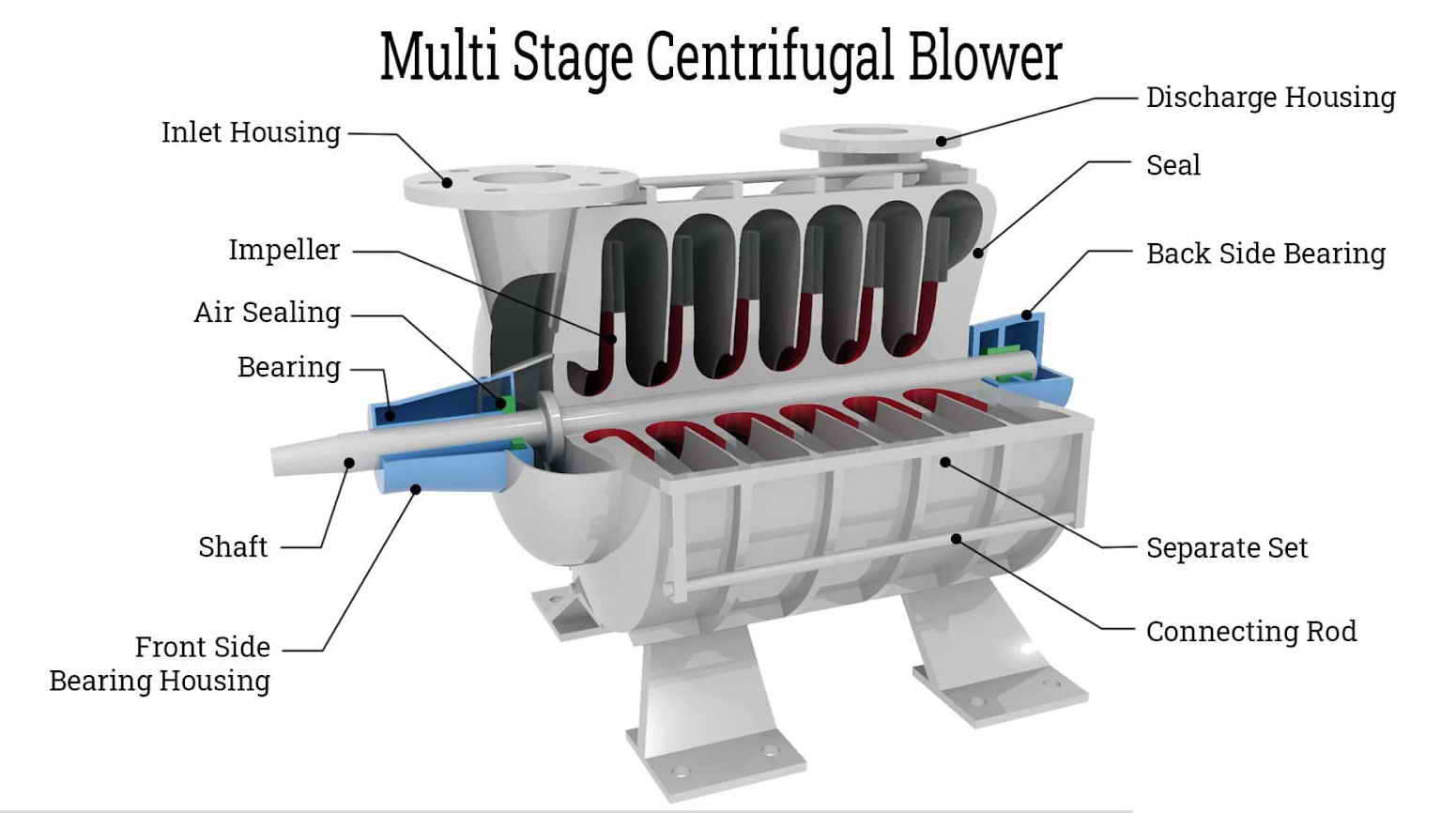

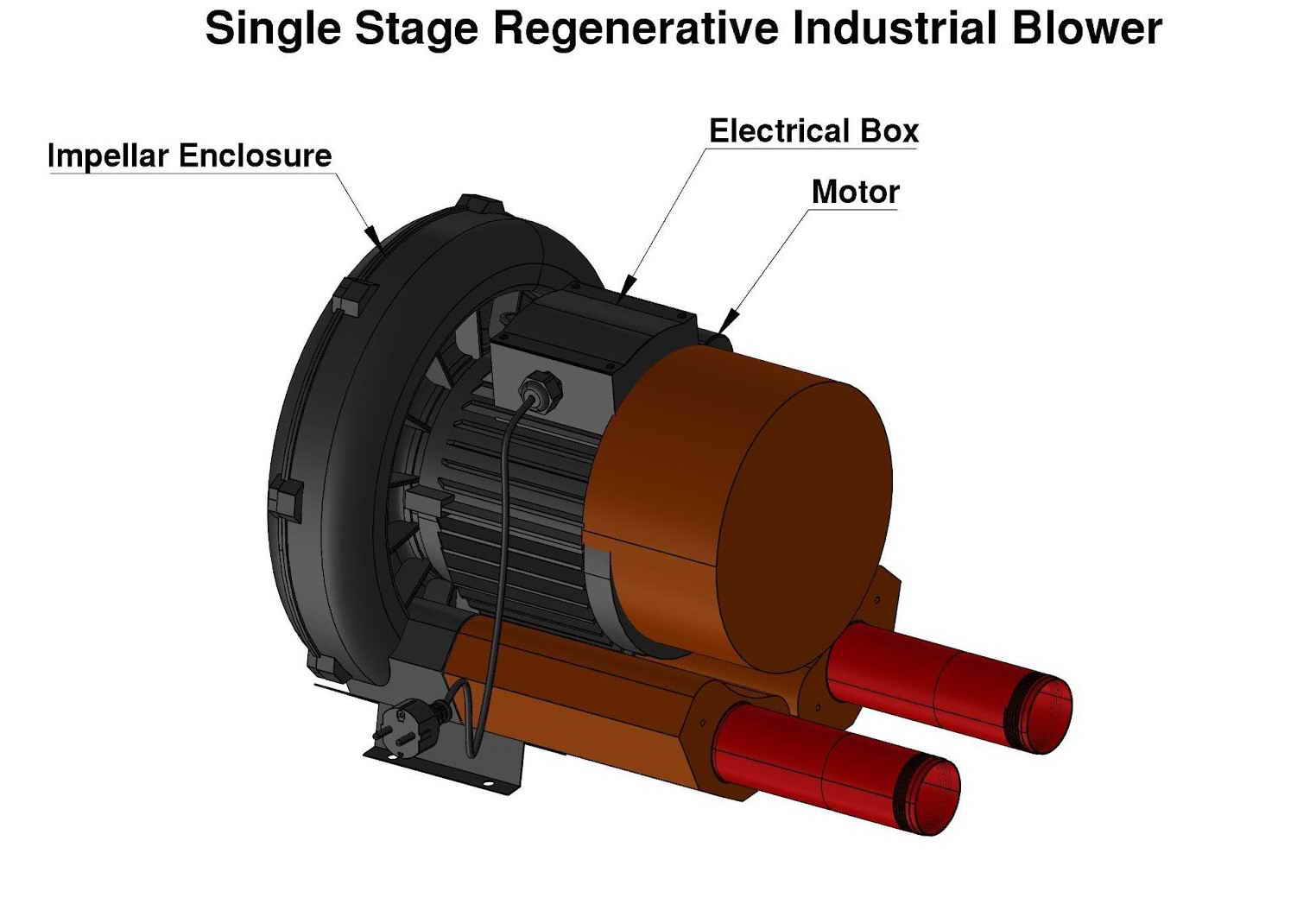

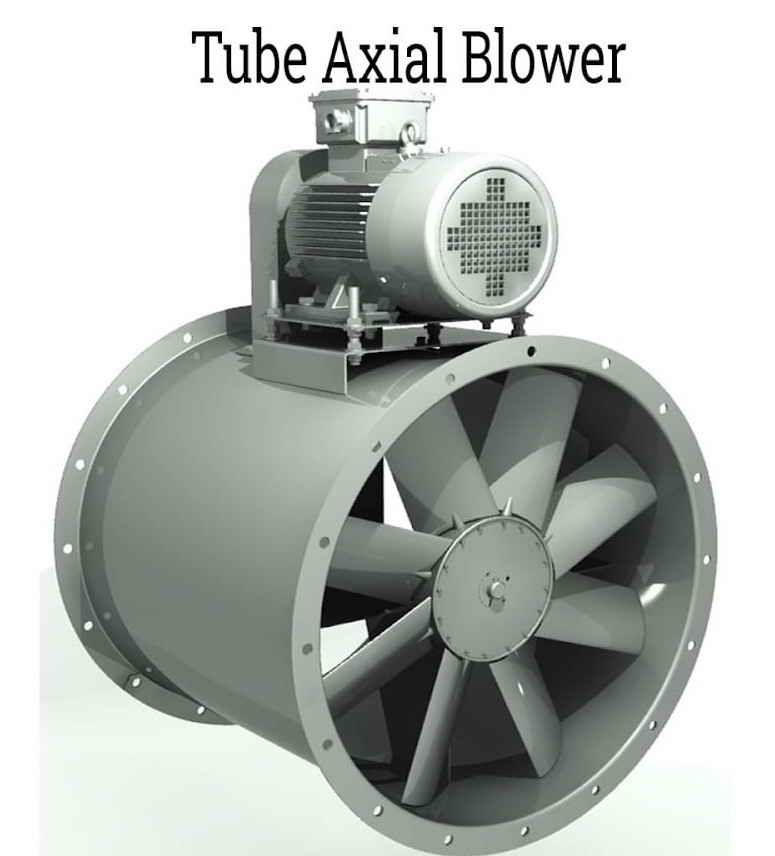

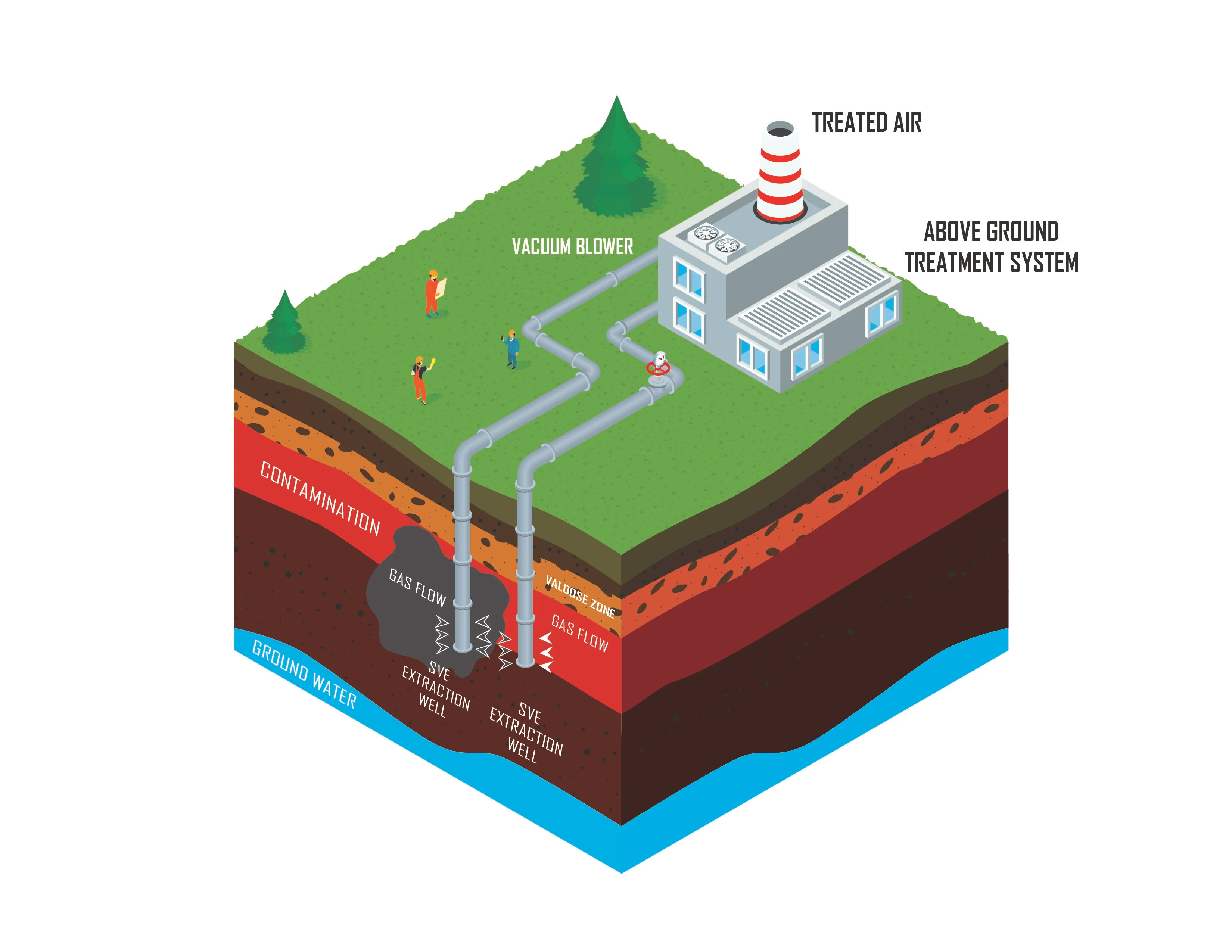

The types of Industrial blowers are centrifugal, multi stage centrifugal, axial, and positive displacement. Centrifugal blowers have a gear system and have a single or multiple stage construction. Axial industrial blower models are simpler to household fans with a central shaft that has blades attached while positive displacement blowers have a rotor geometry.

The classification of industrial blowers is based on the direction of the air flow with centrifugal blowers and axial blowers being the two categories. A centrifugal blower uses centrifugal flow and force while an axial blower uses axial movement.

Industrial Blowers

types:

POSITIVE DISPLACEMENT INDUSTRIAL BLOWERS

-

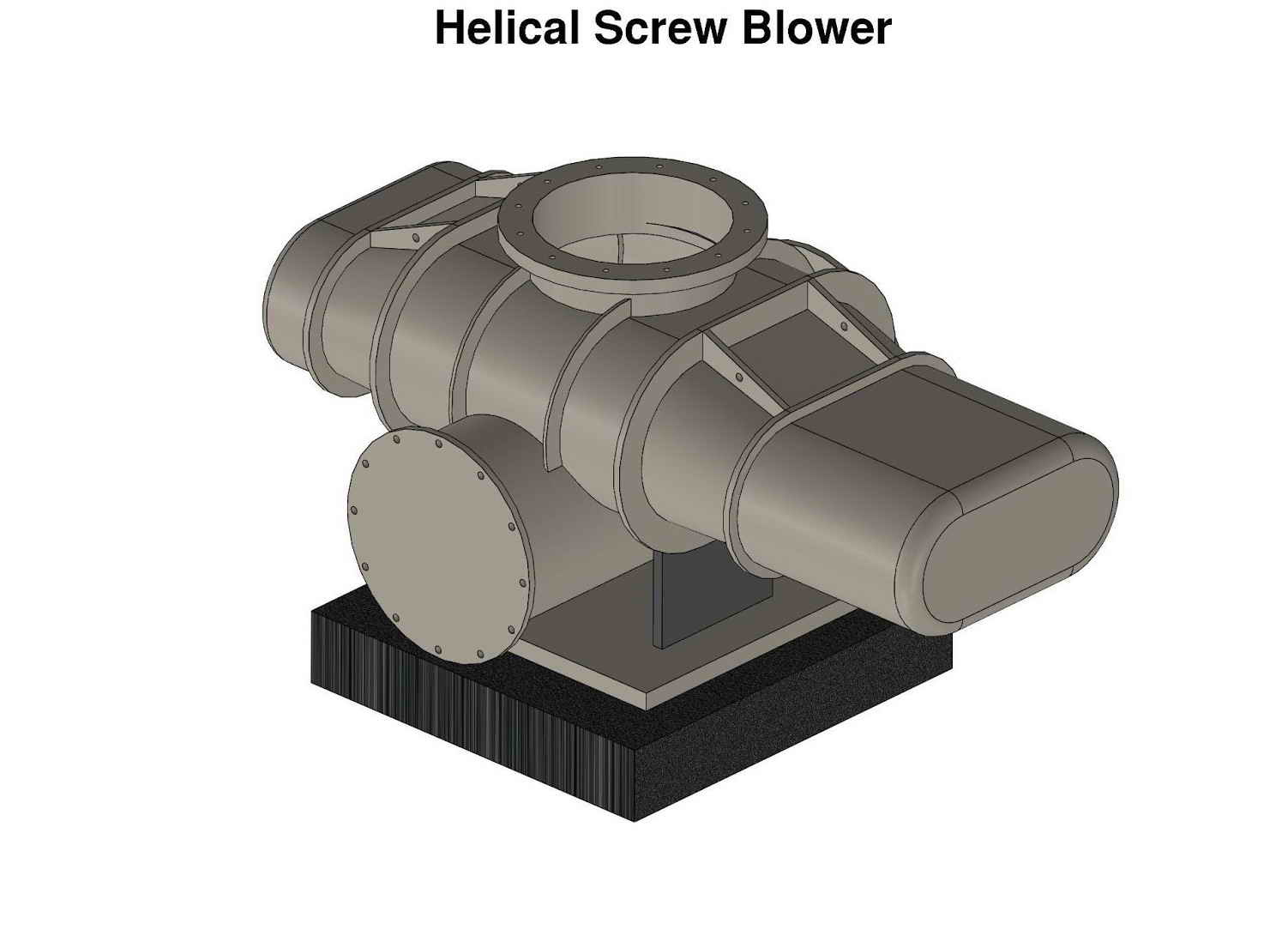

Positive displacement industrial blowers, also known as lobe blowers, release air at a specific time, pressure, velocity, and direction, using a safety valve. The name lobe blower comes from two propellers in the mechanism that counter rotate. Air enters a chamber of the blower and exits through an outlet. This design allows the blower to maintain constant air flow and pressure.

Industries

that use industrial blowers

Benifits of

Air/Industrial Blowers

-

Power Usage:

Industrial blowers offer a variety of outputs due to their various structures and innovations while having a very low use of input power. Since industrial blowers are used in offices, industrial operations, manufacturing, and technical production, it is essential that they be a cost effective part of the operation. All industrial blowers are designed for economical use of power to provide control of electrical costs. Construction, proper installation, and insulation materials are all used to keep costs down and efficiency up.

-

Adaptability:

Industrial blowers are available to fit any form of air and gas movement operations. They come in different styles, designs, sizes, and configurations or can be custom built to fit unique applications. Regardless of the size of the space or the requirements of the application, an industrial blower can meet the requirements. A factor that adds to the adaptability of industrial blowers is the variety of configurations of fan blades, which makes them flexible enough to fit any airflow and pressure conditions.

-

Durability:

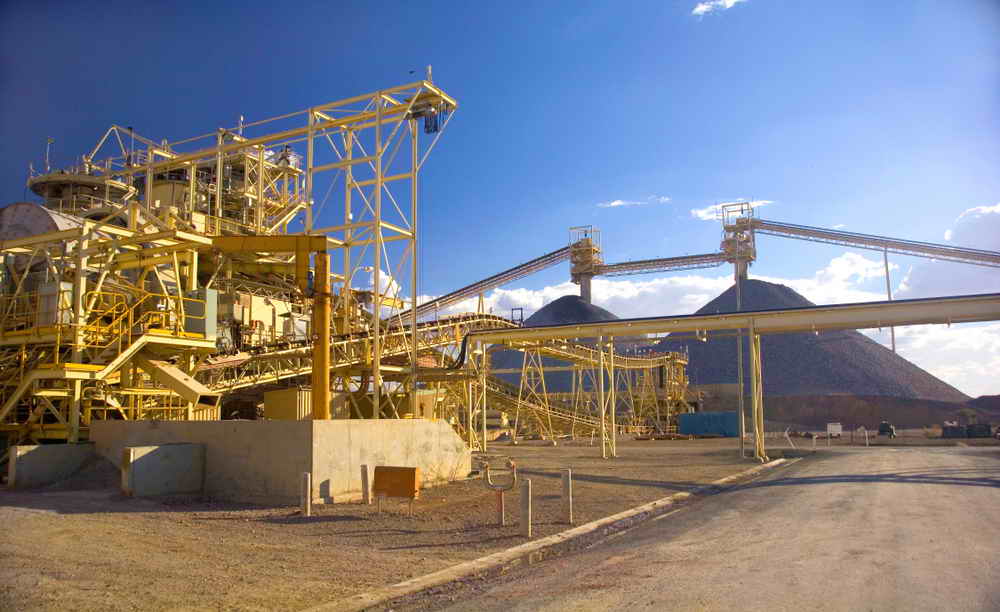

One of the reasons for the popularity of industrial blowers is their ability to withstand the harsh and hazardous conditions that require their use. Hardcore and stressful industries have found that using industrial blowers improves working conditions and productivity while being able to endure the severe nature of the work environment.

-

Ventilation:

A major issue in any workplace is the ventilation system. For harsh conditions, ventilation provides needed airflow to keep conditions cool. In the electronics industry, ventilation is necessary to avoid contaminants on delicate and intricate parts. In either type of environment, air movement and ventilation create a healthier and more pleasant work atmosphere. The advanced ventilation methods provided by industrial blowers remove dust, fumes, smoke, and contaminants to create a safe workplace. Industrial blowers stir up the air in enclosed areas, replacing stale and contaminated air with fresh air.

-

Regulation of Fumes and Smoke:

There are several industrial operations that produce toxic fumes or lung damaging smoke, which has to be removed and exhausted. Under the present environmental restrictions, releasing such contaminants into the air can lead to serious difficulties with environmental agencies. Industrial blowers assist in the alleviation of the problem by using various methods for dissipating dangerous fumes and smoke.

-

The Air Movement and Control Association (AMCA):

Industrial blower manufacturers comply with standards set by the AMCA, which has developed classes to identify the various types of industrial blowers. The AMCA classification method identifies the types and styles of blowers from ones that can be set on the floor of a factory to highly technical ones used for conveying and the control of dangerous fumes.

-

Healthy Work Conditions:

Industrial blowers provide protection against respiratory diseases. The fans, impellers, and blades are designed to vent and cool large spaces. They keep humidity down to keep spaces cool and comfortable. A major health benefit of industrial blowers is the removal of dust, particulates, and contaminants from the air to create a clean air workspace. The removal of these harmful materials prevents respiratory diseases and other health issues.

-

Humidity Control:

Dampness in a room leads to foul smells and bad odors. The nature of industrial blowers is to maintain constant airflow, which prevents the accumulation of unpleasant odors that can lead to non-hygienic conditions.

-

Dust Collection:

The size and volume of air that an industrial blower moves requires some form of collection system. Depending on the operation, that system can involve a receptacle, bag, filter, or some other type of collection device. The simple fact that industrial blowers stir up the air makes it a necessity to have some form of collection method to protect workers. The type and size of the collection is dependent on the size of the industrial blower and the space to which it is directed.

-

Pressure:

Industrial blowers operate at high speeds to move large volumes of air. This results in low to medium static pressure from the radial direction of air movement.

-

Safety:

The motors for industrial blowers have high horsepower and operate at high speeds. This necessitates that the motors be exceptionally durable and reliable, which leads to less overloads and motor damage. The sophisticated nature of industrial blower motors makes them one of the most dependable pieces of equipment a manufacturer or producer can buy. This simple fact makes industrial blowers a very productive and safe investment.

-

Automotive:

The automotive industry makes extensive use of industrial blowers in paint booth ventilation systems and as a means of drying parts and accessories. Industrial blowers play an important part in ventilation systems and airflow for production lines and storage areas.

-

Heat Recovery Systems:

Industrial blowers are an important part of heat recovery systems and are the main element in the air handling unit, which includes an air exchanger, air filter, motorized damper, and bypass damper.

-

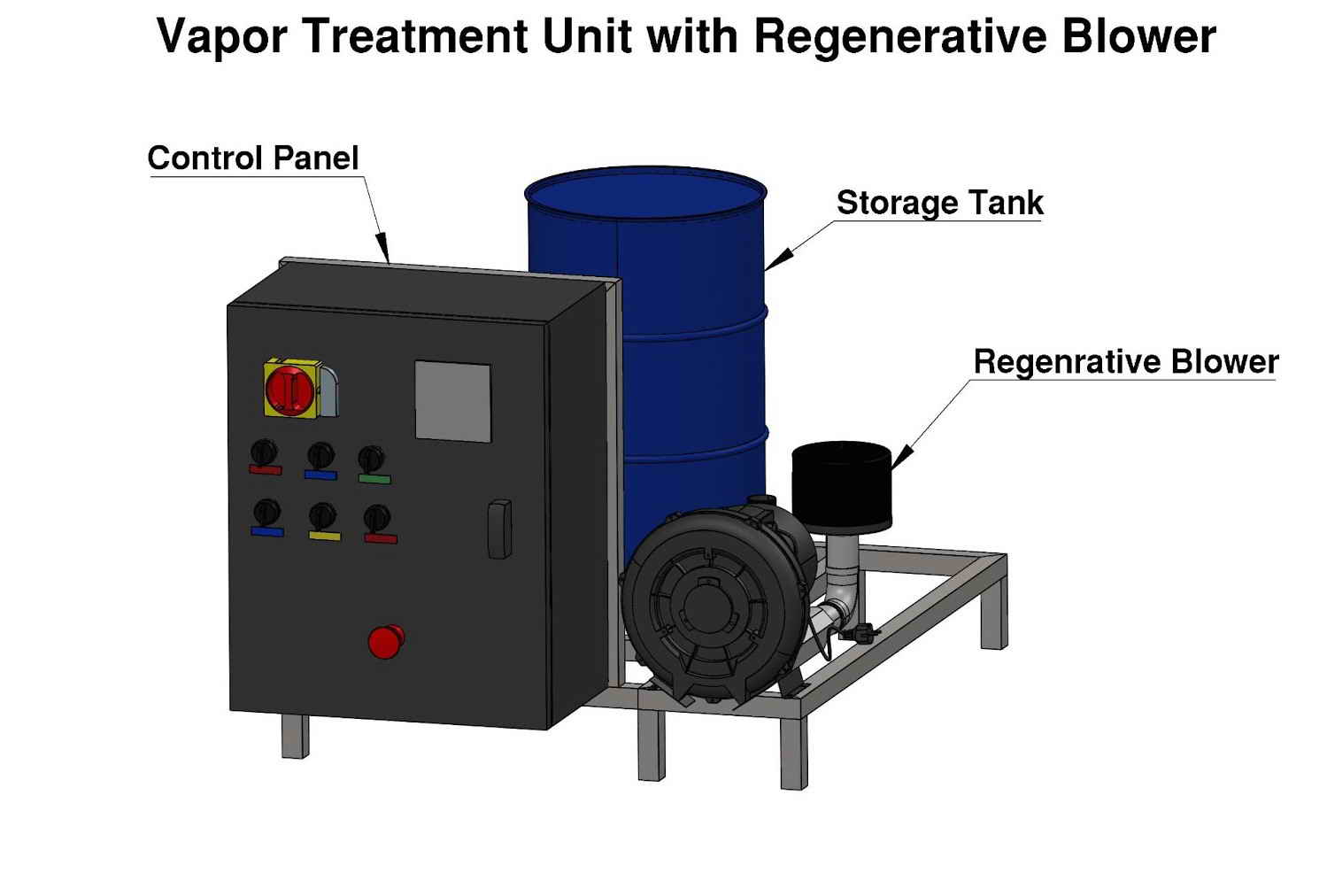

Hazardous Gas Removal:

Industrial blowers are widely used in conditions where hazardous gas is present. Explosion proof industrial blowers are exceptionally strong and resistant to the effects of chemicals and corrosion with inlet cones made of stainless steel, fiberglass reinforced plastic, and polypropylene. These materials are chosen due to their ability to prevent the formation of sparks during the exhausting process.

-

High Temperature Applications:

A unique aspect of the installation of high temperature fans is that they may never be used. They are designed for emergency removal of smoke in case of a fire. High temperature industrial fans must be installed and able to exhaust high temperature air and smoke during a fire. They are made of various types of materials including aluminum, carbon steel, and stainless steel with aluminum being able to withstand temperatures up to 250o F with carbon steel and stainless steel being able to withstand temperatures of 750° F and 1000° F, respectively.